Choosing the right tyres can do wonders for your riding experience, improving comfort, traction and lower rolling resistance for a faster, more efficient ride. They can also be highly durable, lasting for months at a time without a puncture. To help you know what to look for when choosing a tyre, we've created this comprehensive guide of what to know about road bike tyres.

Tyre types

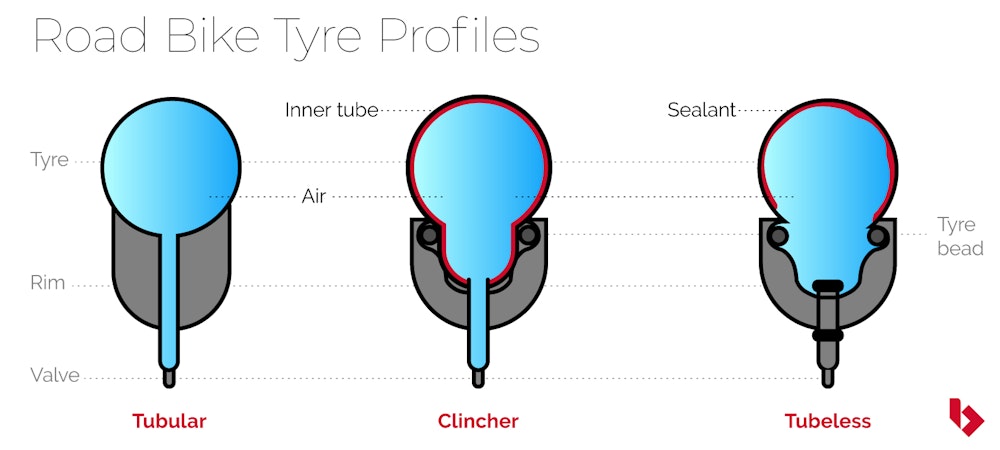

There are three types of road bike tyres that are commonly used, a 'clincher' tyre is the one we are most familiar with. If you follow professional cycling, you'll notice almost all riders prefer 'tubular' tyres, and taking a lead from mountain biking, 'tubeless' tyres continuing to make waves in the road scene. Below is a description of each;

Clincher: These tyres are the most common type and are currently sold with almost every new bike. Clincher tyres require a tube, which, sits in between the wheel rim and the tyre to inflate and hold air. In the event of a puncture, this inner tube can easily be replaced or patched. Clincher tyres feature either steel (aka: wire) or a kevlar fibre bead (aka: folding) on their side, which hooks underneath the ridges of a wheel rim to hold the tyre in place.

Tubular: These tyres are popular with professional riders for the performance benefits they provide, but less popular with recreational riders due to their lack of everyday functionality. Tubular tyres still utilise an inner tube but it is sewn into the tyre rather than sitting separately from it like a clincher, as a result, tubular tyres need to be stuck to the wheel via glue or special tape. The key benefit of sticking the tyre directly to the rim is that in the event of a flat, the tyre will stay on the rim, allowing the rider to continue to roll without losing control.

Tubular wheels are able to save some significant weight over clincher and tubeless wheels by not requiring the ridges for the tubeless and clincher tyre beads to hook onto. Anecdotally, tubulars are also said to feel more supple and provide a better ride quality. On the flip side, changing a flat is tough work, you can't simply swap out a new tube as you would with a clincher, it requires another pre-glued tubular tyre. Furthermore, if your tubular tyre has been glued correctly, it will be extremely difficult to take off with your hands alone. Lastly, tubular tyres are the most expensive option, which another reason for why they're considered an item best reserved for race-day

Tubeless: This technology has long been used in the mountain biking and cyclocross realms and is growing in popularity on the road too. As the name suggests, there is no tube with tubeless tyres, instead, it is just a tyre that hooks onto the wheel as a normal clincher would, but with much tighter tolerances to create a firmer, airtight seal. Sealant is then added into the tyre to aid in plugging small holes and splits, reducing the chance of flats. In addition to a reduction in flats, tubeless tyres provide better rolling resistance than clinchers and can be run at lower pressures, improving traction, comfort and control. It’s worth noting that In order to use tubeless tyres, you'll need a compatible wheelset that will typically feature a hooked sidewall for better sealing of the tyre bead.

[externalhotoffer group="EHO_1"]

Anatomy of a tyre

There are a number of elements that make up a standard tyre that are worth knowing as each will affect performance, comfort, and durability.

Bead: The tyre's bead holds the tyre onto the rim and is only applicable for clincher and tubeless tyres. The bead is typically made from either steel wire or kevlar. Steel wire typically only features on inexpensive, or tyres with more of an emphasis on durability, whereas kevlar beads feature more prominently on premium options. Clincher tyres with kevlar beads are also referred to as 'folding' tyres.

Casing: The casing is the foundation of the tyre, connecting the beads to one another and providing enough resistance from stretch to keep the air in while conforming to the ground surface. The casing is made from either nylon, cotton or silk and measured in 'threads per inch' or 'TPI'. Tyres with a lower TPI count (e.g: 60 TPI) provide good puncture protection but poor rolling resistance, conversely, tyres with high TPI counts (eg. 320 TPI) provide a more supple ride with good rolling resistance but often with reduced puncture protection.

Puncture protection: In order to improve their resistance to punctures many tyres will add a 'sub-tread' layer or 'puncture resistant belt. Some tyres will simply feature more rubber, increasing the thickness of the tread, while others will use specific compounds to enhance their resilience. Sub-layers increase a tyres rolling resistance and can add weight. As such, it is a balancing act for manufacturers to create a fast, lightweight tyre that can offer good levels of puncture protection. Some sturdier tyres designed for winter training and commuting will feature puncture protection in the sidewall too.

Sidewall: This is literally the side of the tyre, and is part of the casing that isn't intended to touch the ground, as a consequence this part of the tyre is the thinnest. Important details such as the wheel and tyre size, and recommended tyre pressure will be found on the sidewall.

Tread: Tread is the part of the tyre that contacts the ground and will be made from varying compounds with different tread patterns depending on it's intended use.

Tyre size

Tyre and wheel sizes for road riding don't vary as much as mountain biking with a 700c wheelsize almost universal for road riding, and tyre sizes typically ranging from 22mm to 32mm. Despite the relatively consistent size options, it's important to know what different tyre sizes mean in terms of performance, comfort, and durability.

Wheel and tyre sizes are governed by an international standard known as 'ISO 5775', a standard designed to make information clear and consistent. The system uses two numbers to detail the wheel and tyre size. The first number refers to the rim diameter in millimetres, in most cases, this figure is '700c'. The second number refers to the tyre diameter in millimetres, in most cases, this ranges from 23mm to 28mm for road tyres but can be upwards of 35mm for gravel, cyclocross and recreational use tyres. So a typical road wheel with a 25mm tyre will be represented as 700c x 25mm.

Previously the standard used was the 'ETRTO' or European Tyre and Rim Technical Organisation', and their markings looked more like this; 37-622. The first number refers to the width of the tyre, and the second number refers to the inner diameter of the tyre. And finally there is also inch markings, which look like this; 28 x 1.40". In this case, the first number refers to the outer diameter of the rim and the second number refers to the tyre width.

The trend in recent times has been towards larger tyres that provide increased comfort and traction, whilst still providing reasonable rolling resistance at the same time. In the past, it was thought that skinnier tyres, pumped up to high pressures were faster, but the latest research suggests bigger and softer is better. Wider tyres can be run at lower pressures providing a more supple ride and also conform better to the road surface and provide additional comfort. Another benefit of larger tyres is the shorter and wider contact patch, which, leads to less resistance and sidewall deformation, resulting in a faster tyre. Specialized recently conducted its own studies into tyre width and resistance, finding that there was almost a 25% reduction of resistance when using a 28c tyre compared to a 21c tyre.

Before you go buying the largest road tyre available, it's important to know that the tyre's width must sit within the recommended wheel rim range and not be compromised by frame clearance, brakes or any additional accessories such as fenders. Consult your place of purchase, or the manufacturer if you're unsure of the limits of your bike.

The Importance of the Wheel to a Tyre

We've discussed the influence tyre size has on performance and comfort but the choice of wheels is just as important.

Modern wheels are becoming wider, not only to accommodate the push for larger tyres but to also improve aerodynamics and comfort. A wider rim is shown to have better aerodynamics than a narrower rim, and the greater amount of air volume provides additional comfort. Rim widths are measured internal or externally, and while external rim width is important for aerodynamics, we're more concerned with the internal rim width, which, influences comfort, rolling efficiency, and tyre shape.

Currently, a narrow road rim measured internally is anything under 17mm, while a wide rim is anything measured internally greater than 19mm. A wider rim will create a wider tyre, and so a tyre marked as being 25mm, may measure above or below this figure when applied to the wheel. For more on road bike wheels, how they influence ride quality and what to look for, read our guide to Road Bike Wheels.

Tread pattern

Road tyres will typically feature a smooth tread surface and are commonly known as ‘slicks’. These offer the highest surface area with the ground on smooth surfaces and provide good levels of rolling resistance and grip. Some road tyres do feature a subtle tread pattern, something that could possibly offer marginal improvements in grip, although data on the subject is inconclusive. Other factors like tyre pressure, thread count, rubber compounds and rim/tyre width are bigger factors when it comes to grip.

A tyre's tread is usually made from butyl rubber and can include additives that provide improved puncture protection, improved grip and/or a splash of colour. Different types of compounds can be used to improve rolling resistance or traction, as such, it's common to see tyres with two or even three compounds in the tread to provide enhanced rolling resistance through the middle of the tyre, but more grip on the edges.

Puncture protection

Unfortunately for the majority of us, signalling back to the team car and swapping a wheel in the event of a puncture isn't a reality, and so, a tyre with good puncture protection is essential.

As mentioned, most tyres will have some additional puncture protection either in the form of a sub-tread layer, puncture protection belt or more rubber. These hard wearing compounds prevent sharp objectives like glass, tacks, and thorns from penetrating into the tube and causing a flat. Manufacturers aim to create an effective puncture protection layer without adding excessive weight or adversely influencing a tyre's rolling resistance.

As well as the inbuilt puncture protection mechanisms, there are a few things you can do to prevent punctures.

Inflation: Under-inflated tyres are more prone to punctures so keep within the manufacturer's guidelines.

Check for foreign objects: A good habit is to regularly check your tyre for any foreign objects that may have embedded themselves along your journey. These small pieces may not cause a puncture immediately, but if you ride with them long enough they will work their way through the tyre and into the tube, eventually causing a flat. If the object has created enough of a hole that you can see the fibres of the casing, it's time for a new tyre.

Replace worn tyres: We discuss below how to check for worn tyres, which, is important as worn tyres are more prone to punctures. As the tread wears down, there's less preventing foreign objects piercing through and causing a puncture.

Tyre pressure

Tyre pressure is a hot topic and in recent times there has been a shift from super high pressure to lower pressure. When the pressure in a tyre is 'high', the rolling resistance is improved and the tyre is less susceptible to punctures. 'Low' pressure in a tyre provides better comfort and grip.

When trying to ascertain the correct tyre pressure, it's far more involved than pumping up the tyre until it's firm and leaving it there. Factors such as rider weight, tyre size, road surface and ride quality will all influence your correct inflation figure.

A general rule is the narrower the tyre or the heavier you are, the more pressure will be required. Exactly by how much you need to raise the PSI (pounds per square inch) per kilogram is up for debate but a common relationship is an additional 1% of tyre pressure for each 1kg. The below table is from one of the world's leading tyre manufacturers, Schwalbe, and provides a good indication of what you should be aiming for.

| Body weight |

|||

|---|---|---|---|

| Tyre width | approx. 130lbs / 59kg | approx. 185lbs / 84kg | approx. 240lbs / 109kg |

| 25 mm | 85 psi | 100 psi | 115 psi |

| 28 mm | 80 psi | 95 psi | 110 psi |

| 32 mm | 65 psi | 80 psi | 95 psi |

| 37 mm | 55 psi | 70 psi | 80 psi |

| 40 mm | 50 psi | 65 psi | 80 psi |

Tyre pressure certainly isn't a set and forget item, you should check your tyre pressure often, about once a week as a minimum. Air will slowly filter through the tube and tyre and given the high pressure and relatively thin tyre walls, this will happen relatively quickly compared to a car tyre. This is particularly important if you're running a tubeless set up as the porous nature of tubeless tyres have a tendency to seep air at a faster rate than clinchers.

[externalhotoffer group="EHO_2"]

Tyre wear

Tyres can last anywhere from 1,000km to 10,000km, and so with such a large variance, it's important to know how to check for tyre wear and replace when appropriate. Most manufacturers will specify a distance range but depending on the road surface, the overall load, riding conditions and tyre pressure, tyres may wear prematurely, so use the recommendations as a guide and trust your judgment if you think it's time to change them.

Many tyres will have wear indicators in the form of small holes in the centre of the tyre to indicate the amount of tread left. Once you can no longer see the dots, your tyre is well and truly worn. As a rule, if you can see the puncture protection belt or the casing of the tyre, it's time for a replacement. If you wanted to be more proactive than that, one of the first signs the tyre is wearing is a squaring off of the tyre through the centre (flat top).

Rolling resistance

Rolling resistant is the resistance from the tyres as they contact the road. The major factor affecting rolling resistance is the deformation of the tyre as it conforms to the road surface and its small undulations. For a road tyre that mostly covers smooth surfaces, higher pressures can be used as there will be small amounts of deformation and resistance as a result. An example where lower pressures are beneficial is on the roads of Paris-Roubaix, where riders have to race across old, cobbled roads. In this scenario, softer tyres conform to the surface, meaning the bike has less vertical movement and more forward movement.

All of the factors we've discussed - tyre width, pressure, construction, tread pattern - influence a tyres rolling resistance, and so the challenge for manufacturers is to create a tyre that performs well in each of these areas, or extremely well in one or two specific areas, race tyres for example.

Typically speaking, tubeless tyres tend to offer better rolling resistance figures than clinchers. This is largely due to the friction between the tube and the tyre being eliminated altogether. What's more, tubeless tyres are also widely regarded for their supple ride quality as a result of the ability to run lower tyre pressures compared to clinchers.

Tubes

If you ride a clincher than the choice of tubes can have an impact on ride performance and overall durability. Much like a tyre, tubes are predominantly made from butyl rubber and a mixture of other compounds that make them elastic enough so they can be used on a variety of tyre sizes, whilst still having thick enough walls to retain air. Tubes can also be made from latex, which, roll better and have higher levels of puncture resistance. The downside of latex tubes is they don't retain air well, and so they need to be inflated regularly, almost daily. As a result, they aren't a popular choice for recreational riders.

Valves are bonded onto tubes in order to be inflated and road tyres have two options; Schrader and Presta. Presta valves (aka - high pressure or 'French' valves) are most commonly found on higher-end bikes and are easy to recognise because they are significantly narrower than Schrader valves. Schrader valves are most commonly found on recreational and entry-level road bikes, they are also the same valves used on car tyres. As each valve is different, unique connections at the pump head are often required to pump up the corresponding tyre. Schrader connections require a pin to push down the spring, whereas Presta valves are opened via the lock ring. Read our How to Pump Up a Bike Tyre article for more information on valve tyres.

We hope this guide has been helpful and provided some valuable information. You can browse BikeExchange for road bike tyres, or search for your local bike shop to get further assistance.